Additional Resources

READY MIX TECH TOPIC:

Concrete Curling

BY DANIEL GREEN

Retired Technical Services Manager, National Cement

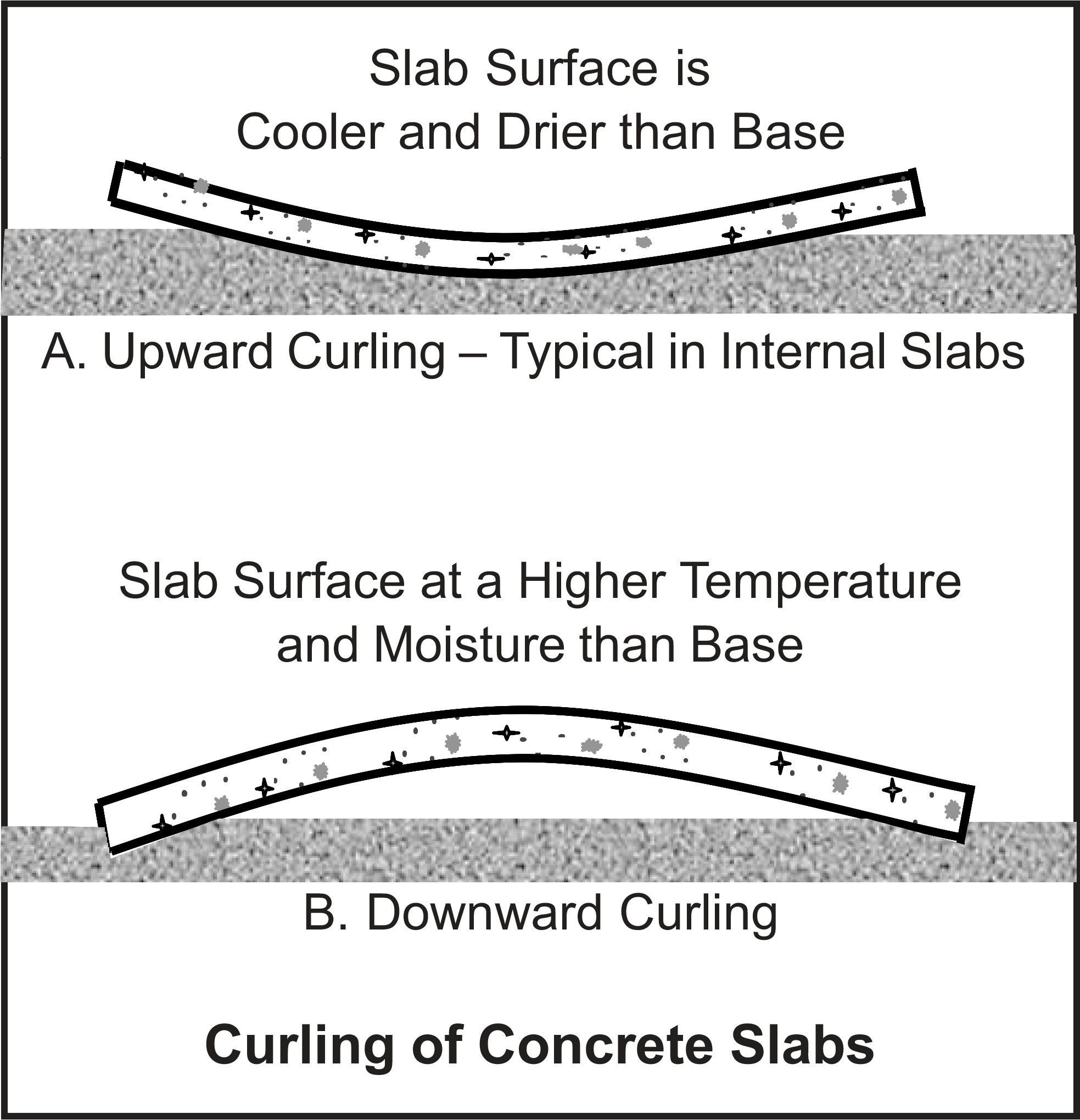

Within a short amount of time, the edges began warping upward and the entire sheet had become what I called “potato chipped”. The hot sun had dried out the top surface and the moist grass below naturally kept the plywood bottom moist. The result: curling….The same thing can happen to concrete slabs.

When the edges of a slab curl upward, they lose contact and support from the subgrade. In effect, the slab becomes somewhat cantilevered. If heavy loadings are applied on these cantilevered areas, such as would be applied by traffic of fork lift truck wheels, there is a good potential for cracking of the slab…usually the crack will run parallel to the joint.

The National Association of Home Builders summarize that curling is caused when the top shrinks more or faster than the bottom, citing variations in moisture and temperature. They continue by stating that slabs that are too thin and control joints that are too far apart are additional contributing factors.

To reduce or prevent curling: to summary and generalize; The PCA discusses the need to use design and construction techniques that minimize shrinkage differentials (between the top and bottom slab surfaces) and by reducing temperature and moisture related volume changes. Further: Thickened edges, shorter joint spacing, sealers, even large amounts of reinforcing placed 2” below the top surface will help.

The NRMCA discusses in their CIP 19 – Curling of Concrete Slabs (to mention only a few preventions) using the lowest water cement ratio, cure the concrete thoroughly, use joint spacing maximum of 24 times the slab thickness (i.e. for a 4” slab: 8’ joint spacing) , increase slab thickness or increase thickness at the slab edges. The remedy for a curled slab (or reducing the curling): Ponding of the slab to reduce curl followed by saw cutting additional contraction joints. To restore flatness across a joint, grinding of the slab surface in the joint area may be required. If a void area exists between the underside of the slab and the subgrade, grout injection to restore support and to prevent breaking off of the curled edges may be required.